With the increase in labor costs, socialized mass production on the production of high efficiency requirements, the realization of production automation has become more and more production-oriented enterprises must be the way of development. In the machinery, product assembly process, parts of the transmission, feeding and assembly operations can be partially or completely semi-automated or automated.

The main purpose of assembly automation is: to ensure product quality and its stability, improve labor conditions, increase labor productivity and reduce production costs. The general requirements of assembly automation is: the production of large batches of products; product structure of the automatic assembly process is good, such as assembly work has a good separability, parts are easy to directional, positioning, to avoid the use of shims and other adjustments; the use of automated assembly should have a better economic results. The degree of automation of the assembly operation often needs to be determined after techno-economic analysis.

Mechanical assembly automation mainly includes automatic transmission, automatic feeding, automatic assembly and automatic control.

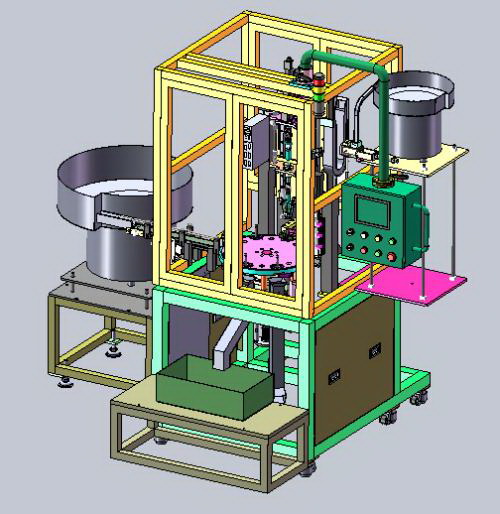

According to the different ways of transferring the basic parts between the assembly stations, the structure of the assembly machine (line) can be divided into two categories: rotary type and direct-entry type. Rotary structure is simpler, positioning accuracy is easy to ensure, fewer assembly stations, suitable for assembly of small and medium-sized parts and products with a small number of parts. The basic parts can be transmitted continuously or intermittently, and in the case of intermittent transmission, the assembly operation is carried out when the basic parts stop transmission. Intermittent transfer is widely used. The structure of the direct-entry type is more complicated than the rotary type, the number of assembly stations is not limited, the adjustment is more flexible, the floor space is large, and the basic parts are generally transmitted intermittently. According to the intermittent transmission of the beat is divided into synchronized and non-synchronized. Synchronous for large batches, few parts, short beat occasions; non-synchronous for free beat, complex assembly processes, manual assembly and automatic assembly combined assembly line. Conveyor devices mainly include rotary table, chain conveyor and non-synchronized fixture-type chain conveyor. All kinds of transfer devices can be used for direct positioning of basic parts or positioning with accompanying fixtures.

Mechanical automatic assembly in a variety of transmission, feeding and assembly operations of the program and mutual coordination must rely on the control system. Commonly used by cams, levers, springs and blocks and other institutions composed of fixed program control system, but when the assembly of components or products have a large change in the structure can not be adapted. If the digital control system is used, it is easy to adjust the process when the assembly parts are changed. Especially microprocessors or electronic computers, with memory and logic functions, can store a variety of work programs for call at any time. This control system is suitable for small and medium batches of multi-species automatic assembly.